Inorganic materials chemistry, Solid state chemistry, Electrochemistry, Secondary batteries, Fuel cells, Biomaterials science, Ceramic biomaterials

Functional and Solid State Chemistry Laboratory, Graduate School of Energy Science, Kyoto University(Phosphorus Letter, 103, 30-35, 2022)

Our laboratory studies the analysis, design, and synthesis of solid-state functional materials for energy, environmental, and biomedical applications. We are developing materials for fuel cells and lithium-ion secondary batteries, focusing on electrochemical energy with a high energy conversion efficiency. Based on the theory of crystal chemistry, we conducted a precise analysis and design of the structures. In addition, we are studying the development of bone repair materials using ceramic synthesis processes based on biomineralization, and the development of microcapsules for use in drug delivery systems.

| Design and Development of Electrochemical Energy Materials | Development of Multifunctional Ceramic Biomaterials |

|---|---|

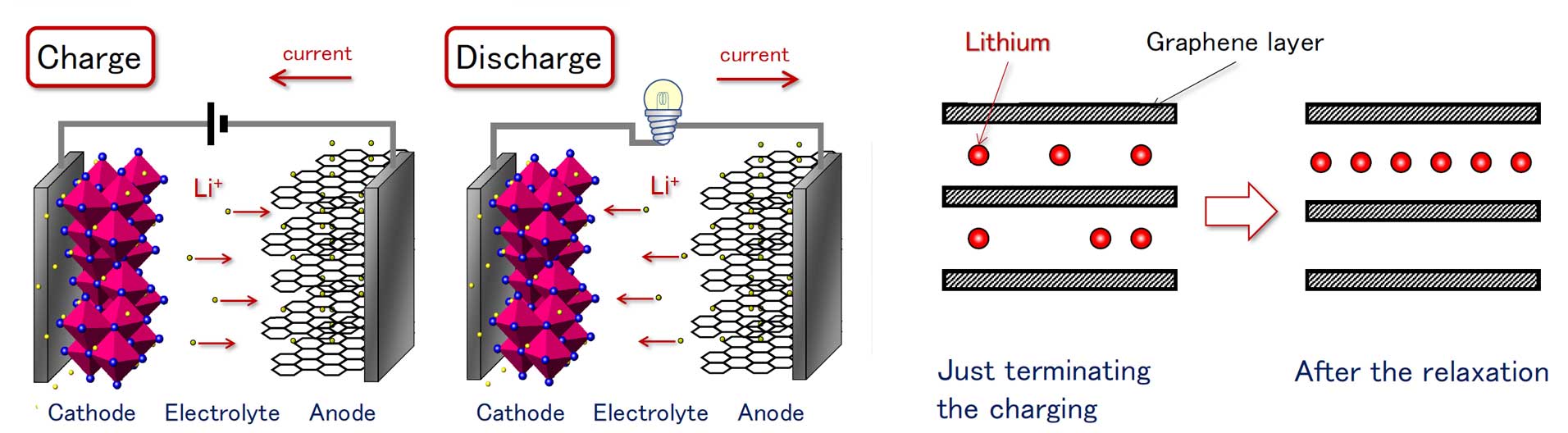

Lithium-ion batteries are indispensable power sources in our modern lives, e.g. for portable devices, electric vehicles (EVs), or power storage for renewable energy supplies, and there is still increasing demand for higher-performance batteries. The lithium ions are extracted from the cathode and intercalated into the anode on charging, while it moves in the opposite direction on working (discharging). We are developing new cathode and/or anode materials for lithium ions to easily intercalate (higher rate performance) and incorporate larger amounts (higher capacity).We also investigate the structural relaxation behavior from the charging/discharging state into the equilibrium. For example, graphite of the major anode material exhibits the stage II structure as the most stable form, in which the lithium ions are intercalated in every other interlayer. However, the lithium ions are intercalated randomly showing stage I symmetry, and it gradually changes into stage II with the relaxation time. Such a behavior was clarified through our structure analysis.

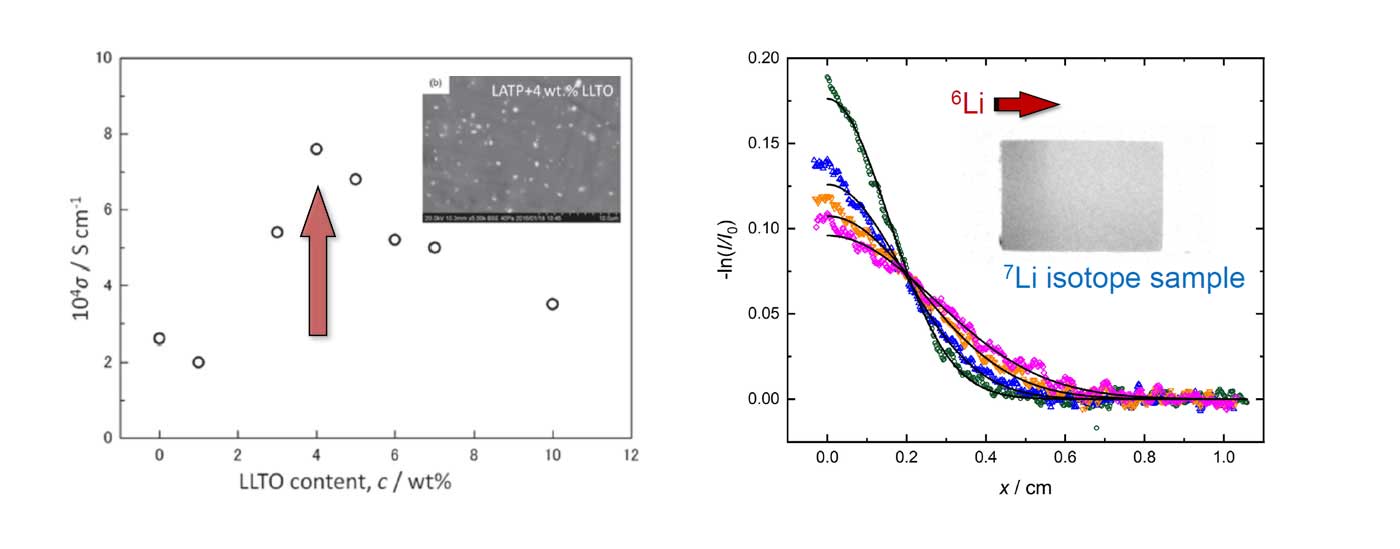

All-Solid-State-Batteries (ASSBs) are intensively studied around the world for higher energy density as well as being free from the leakage of liquid electrolytes and resultant fire/explosion. While NASICON-type structured lithium-ion conductors (LATPs) are promising solid electrolytes due to their relatively high ionic conductivity with good stability in the air, improvement of conductivity is expected. We have synthesized LaPO4-dispersed LATP composites to enhance the conductivity 3 times using the dielectric particle dispersion phenomenon. The increased tracer diffusion coefficients are investigated using the Neutron Radiography technique.

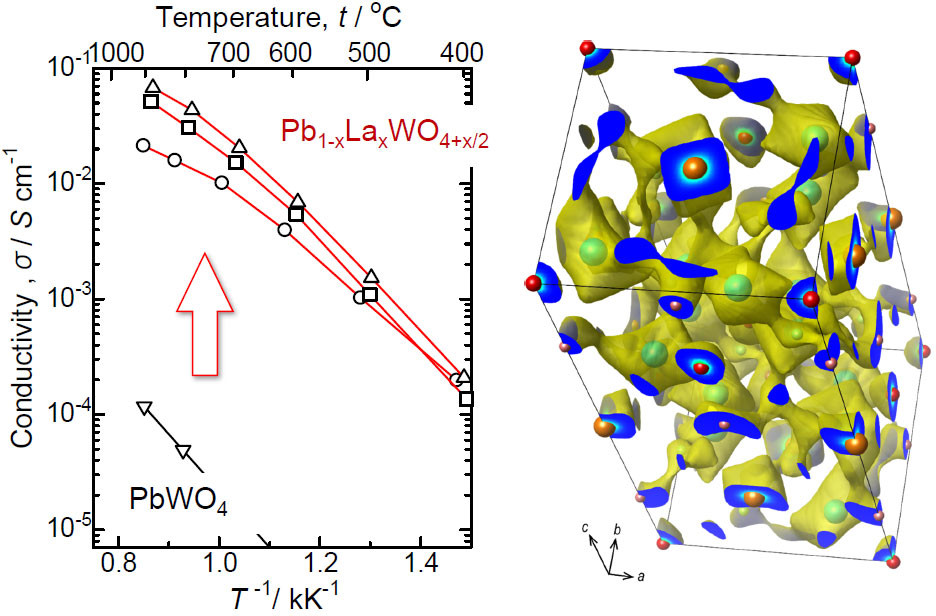

The fuel cell is a clean power generation device that generates electricity directly from the reaction of hydrogen and oxygen to water. Solid oxide fuel cells of high-temperature type exhibit excellent power generation efficiency concerning co-generation without a requirement for expensive catalysts. Ceramic-based ionic conductors including oxide-ion, proton, or hydride-ion conductors are employed as the solid electrolyte. We develop various types of ionic conductors by introducing defect structures. We also investigate the ionic diffusion mechanism through neutron diffraction combined with the maximum entropy method.

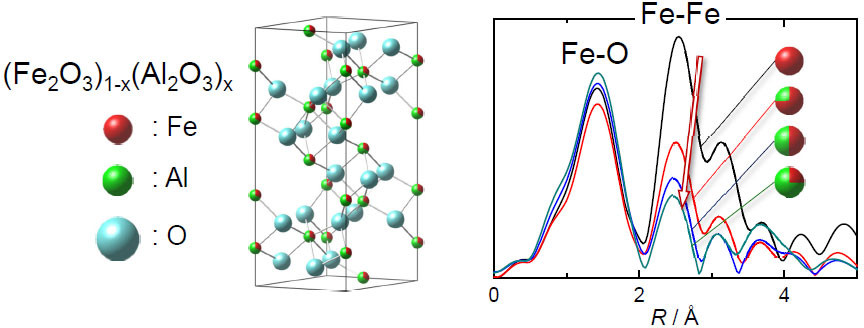

In addition to the materials for batteries or fuel cells, we are also developing various kinds of new materials. For example, we were the first to synthesize the corundum-type structured Fe2O3-Al2O3 solid solutions in the overall compositional range. While the most stable oxide forms of iron and aluminum are corundum-type structured α- Fe2O3 and α-Al2O3, respectively, the solid solution range is much restricted due to the difference in lattice parameters. We have successfully formed the metastable solid solutions through the mechanochemical method. The atomic-order cation mixing is confirmed by TEM, EXAFS, and Mössbauer spectroscopy in addition to XRD. In addition to the anode materials, we are considering various applications.

The potential of apatite is to connect everything, from inorganic materials to cells. Establishing an "Apatite Science" that contributes to the realization of a "Medical-less Society." (2022.03.11) (in Japanese)

The potential of apatite is to connect everything, from inorganic materials to cells. Establishing an "Apatite Science" that contributes to the realization of a "Medical-less Society." (2022.03.11) (in Japanese)

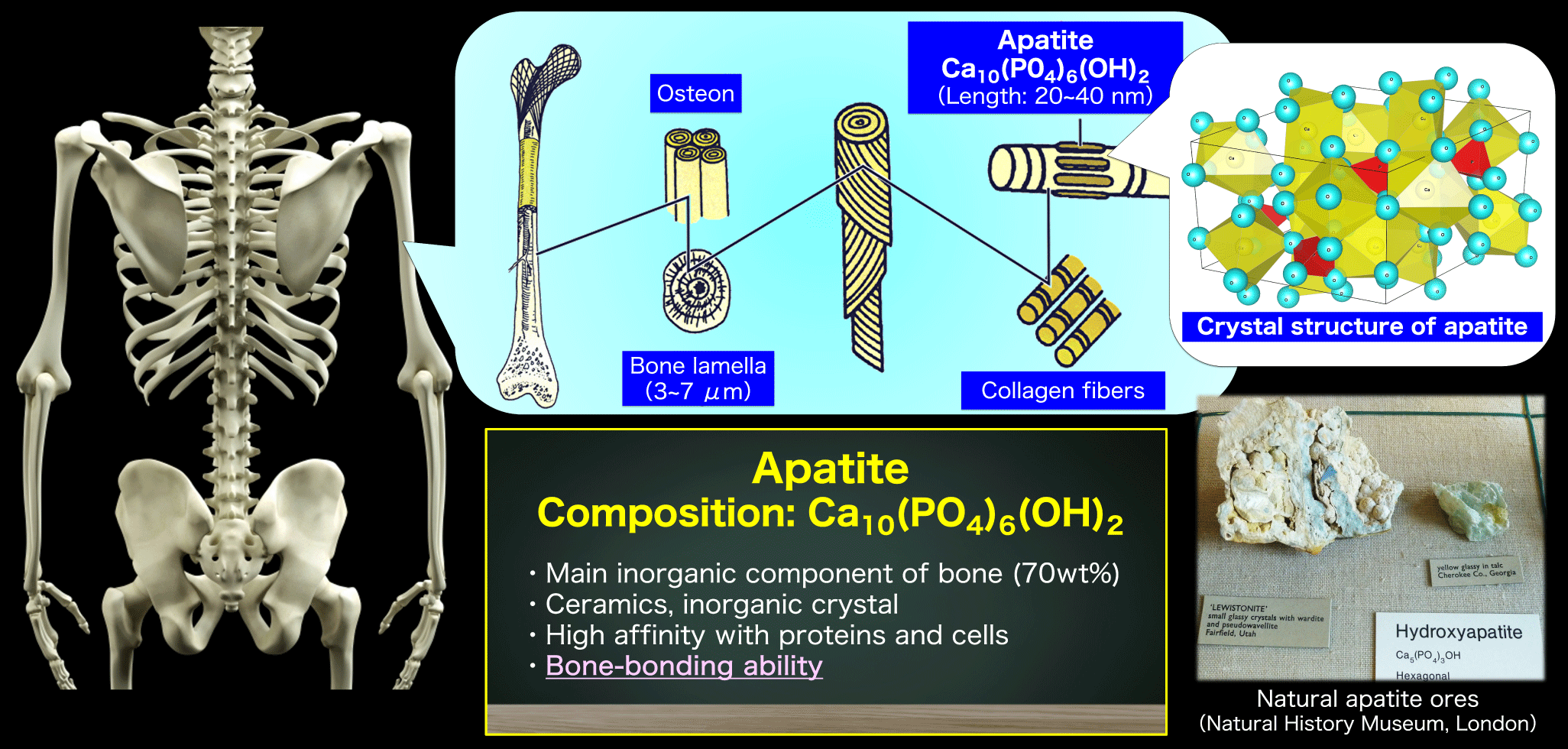

Living bone is a composite of apatite crystals that form a complex three-dimensional structure with collagen. In nature, living organisms synthesize this composite at ordinary temperatures and pressures. In our laboratory, we are developing biomaterials that can express various functions in the living body by focusing on the high biocompatibility of apatite (Ca10(PO4)6(OH)2, etc.), a unique biomaterial that constructs the skeleton of living organisms, and the biomimetic method, which is a ceramic synthesis process based on biological activities.

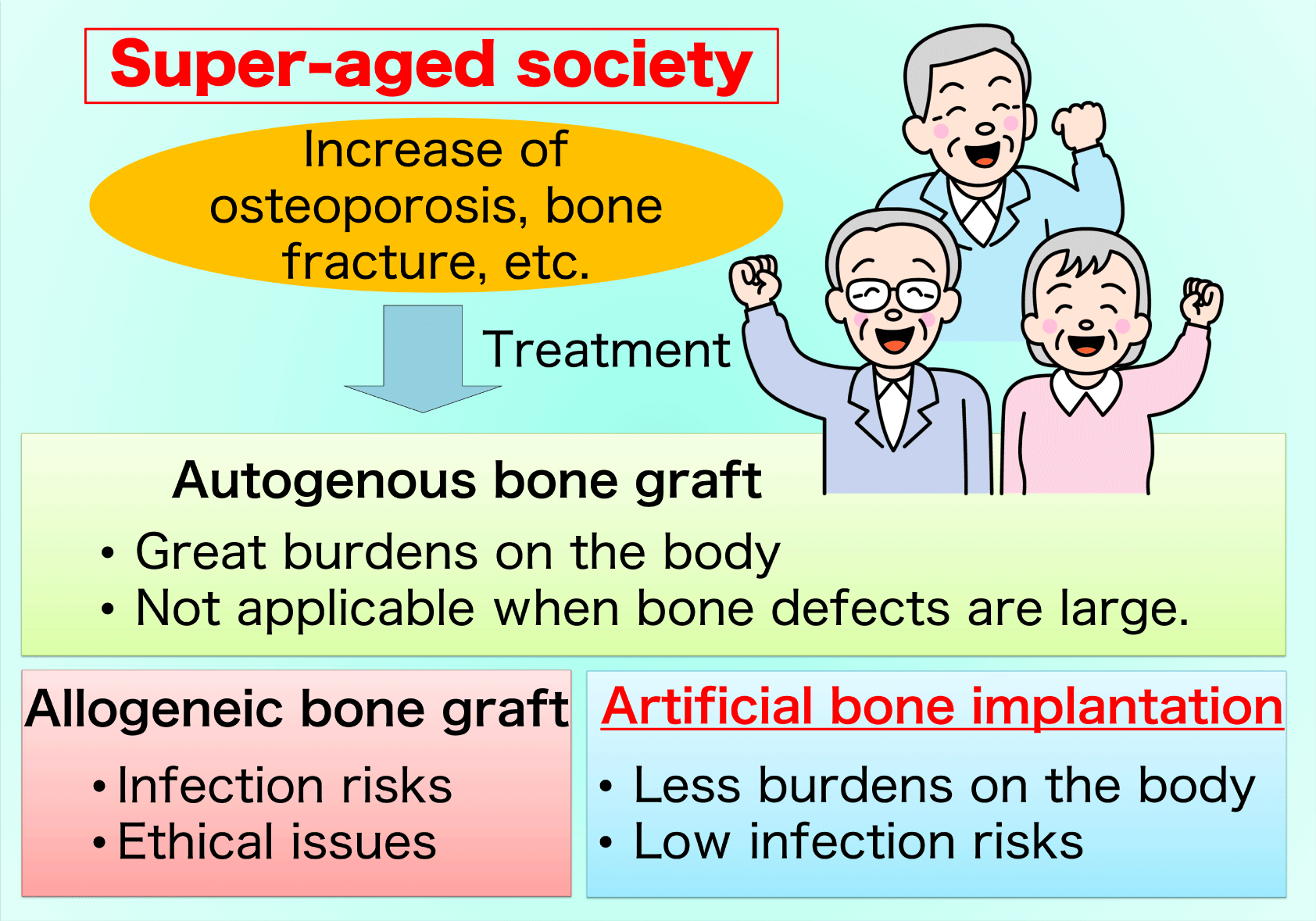

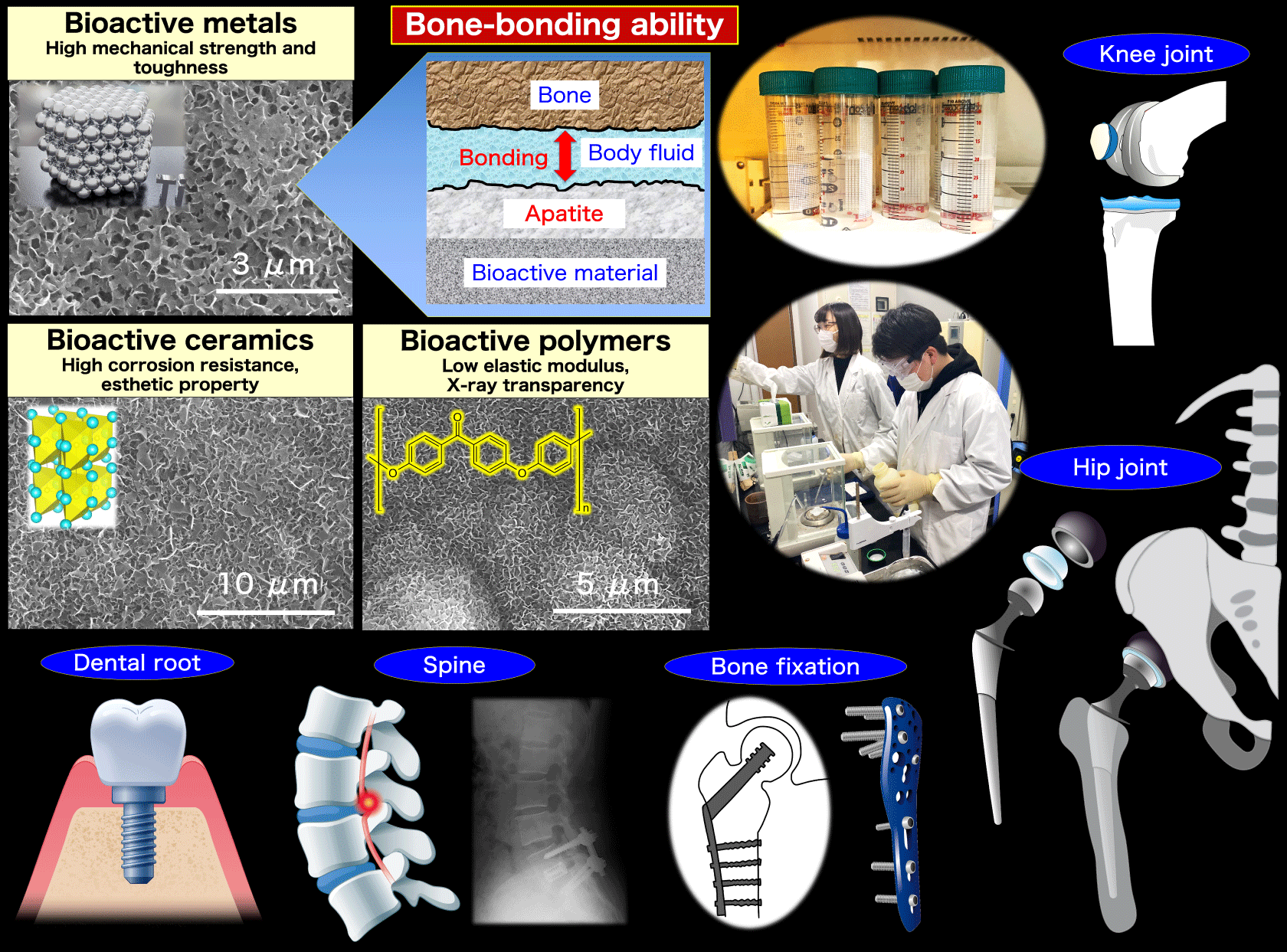

Certain ceramic materials naturally bond and integrate with surrounding living bone in bone defects. Since the invention of the first bone-bonding glass material (Bioglass) by late Prof. Hench at the University of Florida in the early 1970s, the development of bone-bonding ceramic materials has been actively pursued worldwide. However, ceramic materials, such as glass, are inflexible and vulnerable to impact, limiting their use as artificial bones. In current clinical practice, there is a need for bone repair materials that exhibit faster, more substantial, and more extended bone-bonding properties than conventional materials and high mechanical strength and flexibility to meet the appropriate mechanical properties for the site of use. In our laboratory, we are focusing on the "biomimetic method," which is a ceramic synthesis method based on biological activities. We are developing bioactive materials useful for bone repair for orthopedic and dental applications using a synthesis process based on material chemistry, crystal chemistry, solution chemistry, and biological chemistry.

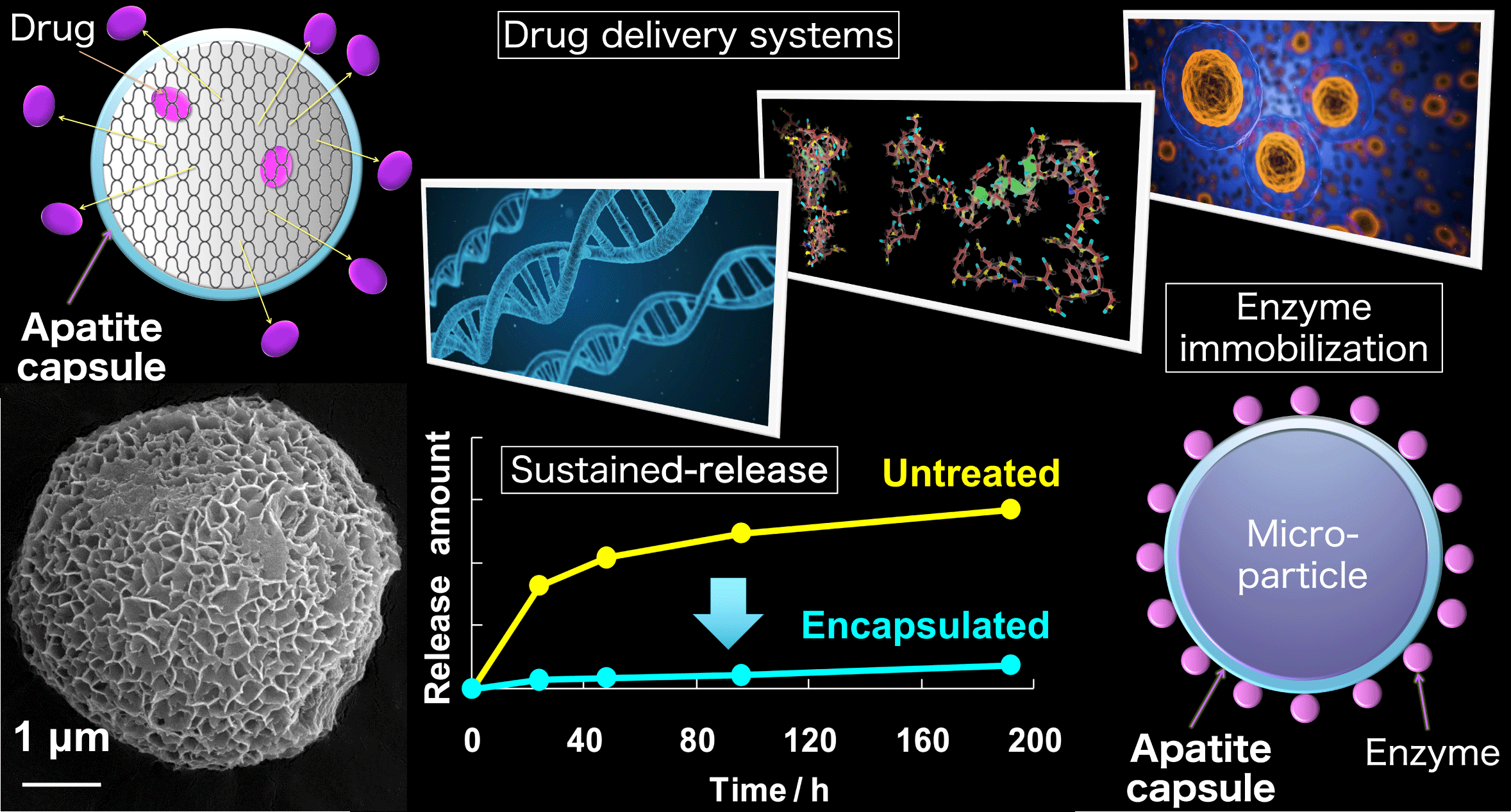

Microcapsules and hollow microspheres are expected to be used as carriers for drug delivery systems (DDS) and antibacterial materials by encapsulating various drugs and functional materials. In our laboratory, we are trying to develop microcapsules consisting of apatite, a major inorganic component of the bone. We are studying advanced medical materials useful in various medical fields, such as DDS, gene therapy, and environmentally compatible functional materials with antibacterial and water purification functions.